After water damage, restoring the affected property while minimizing environmental impact is a delicate balance. Traditional restoration methods, characterized by extensive teardowns and material replacements, can significantly contribute to waste generation and resource depletion. However, recent innovations in the water damage restoration industry have led to the popularization of in-place drying. This more sustainable option focuses on saving materials and structures while effectively addressing water damage.

Certified Restoration is proud to reduce waste in the restoration industry by utilizing environmentally friendly techniques like in-place drying. This blog post will explore how this approach aligns with sustainability principles in water damage restoration.

What is in place drying?

In-place drying is a technique used in water damage restoration that focuses on drying affected areas without removing or replacing existing materials. This differs from traditional restoration methods, which typically involve tearing out and replacing materials to "start fresh" after water damage. The ultimate aim of in-place drying is to keep the original structure and its contents intact whenever possible.

What are the environmental benefits?

This method focuses on 2 of the 3 R's: reduce and reuse. Because in-place drying aims to preserve existing building materials and restore them to their pre-damaged state, fewer building materials are sent to landfills during the restoration process, and no new materials must be purchased or created to restore the home.

What kind of materials can be preserved?

In-place drying effectively preserves hardwood flooring, wood cabinets, drywall, carpeting, and upholstery.

- Hardwood flooring: In-place drying extracts the water from under the floorboards without moving the wood panels or taking the whole floor apart.

- Wood cabinets: Advanced moisture-eliminating technology can dry-soaked wooden cabinets, saving you the hassle of demolishing and reconstructing them.

- Drywall: Soaked drywall is especially susceptible to mold and must be treated immediately. The Injectidry system, discussed below, can extract moisture from the affected areas without tearing them down.

- Carpeting and upholstery: Carpeting and upholstery can be preserved after a water damage event using similar techniques to removing water from hardwood flooring.

What are the other benefits of in-place drying?

In addition to reducing the environmental impact of the water damage restoration process, in-place drying has a number of other benefits:

- Saves money: Drying in place reduces the need for tearing down and replacing materials, which can be costly. Property owners can save on repairs by keeping the existing structure and materials.

- Speedy and efficient: Traditional restoration methods are often more labor-intensive and lengthy when waiting for new building materials. In-place drying speeds up the restoration process, allowing property owners to get their homes back to normal more quickly.

- Less invasive: Drying in place minimizes disruptions to the premises and its occupants, allowing them to continue their daily activities. This is particularly advantageous for businesses, as they can remain operational during the restoration process.

- Retains property value: Maintaining the original structure and materials via in-place drying helps uphold the property's worth and structural soundness.

How does Certified Restoration harness in-place drying?

Certified Restoration primarily uses the Injectidry system to dry flooring and the XPower Viking PDS-21 Wall Cavity Dryer to dry drywall after water damage. The Viking uses heated pressurized airflow for cavity drying, eliminating the need to cut out and replace drywall. The Injectidry system utilizes negative airflow that creates suction, allowing it to pull water trapped beneath the surface.

Injectidry panels are placed around the affected flooring and fastened with an airtight seal when used in a restoration project. The panels are connected to the Injectidry system through hoses. Warm, dry air travels through these hoses and creates suction between the panels and the floor. The intense suctioning removes moisture present in the deepest pores of the floor or drywall. The excess moisture is then completely eliminated from the floor and retained in the Injectidry system tank.

The Injectidry system and the Viking Wall Cavity Dryer are the fastest and most effective ways to draw trapped moisture out of floors and walls, cutting down overall drying time. This reduces the chances of cupping or warping and gives mold and mildew a slimmer chance of developing.

In addition to the Injectidry and Viking systems, our team uses the following equipment to accomplish in-place drying:

- The Drymatic Wall System is designed to efficiently control the heated airflow created by the DBK Drymatic Boost Box/Bar. The system uses micro-jets of warm, dry air to break the boundary layer of moisture at the surface of a water-damaged material. The controlled heat generated by the Boost Box/Bar is then driven into the structure, increasing the core temperature and the bound water's diffusion rate.

- Moisture meters measure the amount of moisture in walls and floors and assist technicians in tracking the progress of moisture extraction.

- Dehumidifiers reduce the overall moisture in the environment to decrease humidity and prevent condensation.

- Air movers are high-powered fans that produce a concentrated airflow to promote evaporation and air circulation.

Conclusion

If your property has water damage and the water source is Category 1 (a clean water source), finding a restoration company that uses in-place drying techniques can help you reduce the environmental impact of your home's restoration project, save money, and get your property back to normal faster.

Certified Restoration's IICRC-certified technicians are ready to tackle any water damage restoration project. We offer 24/7 emergency response and are fully licensed, insured, and IICRC certified. For a trustworthy, responsive, and environmentally-minded water damage restoration company that can help you get your home back to normal, contact Certified Restoration at (619) 234-2500.

Disclaimer

This article is for general information ONLY and is not intended to be legal, medical, or scientific advice. The proper approach to each project must be determined on a case-by-case basis. Certified Restoration always recommends that you call a certified restoration professional, especially when there are children, elderly, or individuals with health conditions residing in the property.

Related Posts

-

Water Damage and Your Air Conditioner

Summer is coming! We can't wait for beach days and BBQs, but we know that…

-

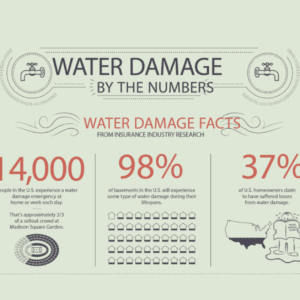

WATER DAMAGE by the numbers

Courtesy https://www.waterdamagedefense.com/

-

Water Damage and Your Air Conditioner

Summer is coming! We can't wait for beach days and BBQs, but we know that…